Our Manufacturing Strength

The company offers a complete production process from design to application, with annual capacities of 40,000 tons in aluminum extrusion, 18,000 tons in vertical and horizontal electrostatic powder coating, and 12,000 tons in anodizing.

In our advanced mechanical processing facilities, we have the capacity to process 1,000,000 products annually. Profiles are delivered in customized forms with precise tolerances, ready for assembly. Operations such as cutting, drilling, and disassembly are carried out meticulously using CNC-controlled machines.

Our facilities produce high-quality aluminum profiles using billets with diameters of 4", 5", 6", 7", 8", and 12", in alloy groups including 6060, 6063, 6463, 6061, 6082, 6005, 5083, and 1050. Each stage of the production process is carefully controlled through chemical and metallographic analysis, dimensional inspection, and surface testing.

Upon customer request, heat treatments such as T4, T5, T6, T64, and T66 are applied in our aging facilities to enhance the mechanical performance of the profiles. For surface finishing, coatings are applied in compliance with QUALICOAT standards at Class-1, Class-2, and Class-3 levels, ensuring both aesthetic quality and durability.

By combining production strength with design precision and engineering excellence, Aluminance continues to serve as a reliable solution partner for contemporary architecture and industrial applications.

Divisions

Foundry Facility

With an annual production capacity of 25,000 tons, the foundry produces billets in 4” to 8” diameters using alloys such as 6060, 6063, 6463, 6061, 6082, 6005, 5083, and 1050. Throughout the casting process, each billet undergoes rigorous quality control, including detailed chemical and metallographic analysis, ensuring consistent precision and reliability.

The facility operates with three 20-ton melting furnaces, two homogenization furnaces, and one cooling furnace—delivering efficient, high-quality billet production aligned with international standards.

Tooling Department

With an annual production capacity of 2,000 dies, the die shop utilizes advanced CAD/CAM/FEA software for precision engineering and manufactures components using high-accuracy CNC machining centers. Continuous quality control is maintained through chemical and metallographic analysis of the steels used in die production.

To maximize performance and extend tool life, all dies are stored in specialized ventilated environments. Additionally, gas nitriding is applied to enhance surface

Extrusion Press Line

The press lines have a total annual extrusion production capacity of 40,000 tons, producing billets with diameters ranging from 4’’ to 12’’, and manufacturing high-precision profiles suitable for both architectural and industrial applications.

Throughout the production process, dimensional measurements and surface analyses are conducted using Romidot devices to ensure full quality control. Based on customer requirements, aging treatments such as T4, T5, T6, T64, and T66 are applied to enhance the strength and durability of the profiles.

Anodizing Facility

With an annual production capacity of 12,000 tons, the facility carries out matte, bright, and colored anodizing surface applications. During the production process, regular analysis of bath chemicals and continuous monitoring ensure maximum coating quality, while thickness, brightness, and corrosion resistance tests are conducted after coating to complete the quality control process.

All processes are carried out in compliance with international QUALANOD standards.

Electrostatic Powder Coating Facility

With a total annual production capacity of 18,000 tons, the facilities also produce insulated profiles with heat barrier lines. Surface coatings are applied in compliance with QUALICOAT standards in Class-1, Class-2, and Class-3 categories, offering a wide range of color and texture alternatives in accordance with the RAL color scale, ensuring design freedom.

Pre- and post-coating chemical analyses and quality control tests are performed, measuring coating thickness, surface brightness, and corrosion resistance to ensure the highest quality standards are met.

Wood Coating Facility

With an annual production capacity of 700 tons, the facility uses advanced application techniques to apply custom patterns on the inner or outer surfaces of profiles. burada silinen cümleye dikkat -

Coatings provide high UV resistance and protection against environmental effects, while offering a variety of colors and patterns to meet different design needs.

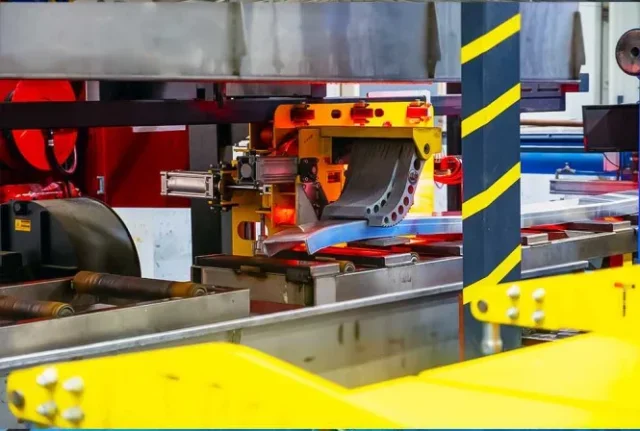

Mechanical Processing Facility

The facility, with an annual processing capacity of 1,000,000 units, offers profile processing up to a maximum length of 7.5 meters. Operations such as cutting, drilling, milling, and disassembly are meticulously carried out on fully automated CNC machines, with high-precision dimensional measurements and quality control ensured using Romidot devices during the processing stages.

Precise processing solutions for complex geometries, tailored to customer demands, are provided, and the products are delivered ready for assembly.

Composite Panel Facility

At Zahit Alüminyum’s composite panel facility, A2, B1, and B2 fire-rated panels are produced under the Aluminance and Vetrina brands. With an annual production capacity of 1,500,000 m², the facility offers a wide range of color options suitable for architectural façade cladding and various other customized applications.

The aluminum composite panels are manufactured in compliance with TS EN 13777 standards, with aluminum skin thicknesses ranging from 0.20 mm to 0.50 mm, in widths of 1000, 1250, and 1500 mm, and lengths from 2000 to 6000 mm. Quality control processes include paint testing, dimensional inspections, and adhesion tests to ensure the panels meet the required performance standards.